-

Posts

864 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Events

Gallery

Blogs

Posts posted by Adam001

-

-

Another vote for Irwin extractors here...they are the right tool for the job

Failing that, welding will work, you'll need to do some pretty destructive welding for the heat to damage the seal

-

2nd is for the R380 gearbox, you need the 1st link.

Both are for the LT77. Mine is fitted with the second one. I believe they are interchangeable, the second is just a better design and doesn't require adjustment

-

Depends, I would just join them all up together to a rated connector onto a cable of adequate capacity, like taff says. Most OEMs do it that way and there's nothing wrong with it... something like...

-

Rewired mine with nothing going through the chassis, all kept up high...the chassis is for holding all the mud

-

do you have any ideas about 150 amp alternator?

what make? where was instaleld?

You can find them on quite a few cars. I personally have 2 alternators, an uprated 200tdi alternator (120amp) in the standard location, simple bolt on job and a Renault Laguna 150amp alternator on a custom mount on top of the timing chest. I have pictures if they are of any use. You can buy straightforward dual alternator kits for the 300tdi.

-

That alternator will theortically work, but you will need to check the mounting position of it, pulley shaft diameter (if swapping pulleys) or multivee number (if using the pulley it has). I would expect to have to do some custom fabrication to fit it to the block.

That alternator however also needs to be plumbed into the engines cooling system and have plenty of flow otherwise it will burn out almost immediately, that design traps all the heat in and the coils just burn out.

The standard wiring from the alternator to the starter will not cope with 190amps. you will need to fit full 35mm^2 cable to cope with that level of continuous power (25mm may cope if the insulator is very high quality).

My personal recommendation is don't bother, find a air cooled 150amp alternator and fit that instead.

-

So how is a spade connector or a taped up solder joint any less exposed to moisture ingress. Also consider that most connections for towing are made inside the vehicle. And you would test it in the same way you test any connection

Never said a spade connector or a taped up solder joint is any better.

I use soldered joints only in straight lines with strain relief planned in. The joint is then covered by raychem spec heatshrink (preferably adhesive lined, but not always as I'll admit it's expensive stuff) with a layer of self extinguishing insulation tape.

Spade connectors can be fine if the correct ones, you can get a good connection but I still don't use them for high current applications, best ones are chemically stable double crimp copper, I apply a small amount of solder to the second crimp to seal the ends of the strands then cover the rest with 3mm heatshrink for 1-3mm^2 cables and 4-5mm for 3mm^2+ cables with 9.5mm spades.

I don't personally even like spades all that much, pin connectors are easier to seal in purpose made housings, but lots of kit still need spades.

How can you test the scotch lock? A resistance check will show it as perfect unless you have a expensive multimeter that can read very low values and compensate for it's own leads, you have to load it with the full fuse current, not 21W for instance, typically must be able to handle 72W or 144W, you have to plan for worst case. A connection you can see or feel is always better for reassurance.

-

Simple way to deal with electric systems, treat them with the respect they deserve, if you know what you are doing, go to town, if you don't, ask someone in the know nicely to help out.

Massively different cross sectional are and increased resistance according to a mate who's an electrical engineer. All I can tell you is that the NAS ones blink at the normal rate with sensible cables. I don't do electickeryTell your mate to take his degree back...he got ripped off. However, to your average joe it is a perfectly viable conclusion (but not acceptable from a electrical engineer). Think of it as a straw vs a industrial storm drain.

Believe it or not, even professional Tow Bar fitting companies use Scotch Locks by the thousand in a year. The come back rate is very low.When used on low current systems like side lights ( 21watts and below) they can be a very effective connection.

If fitted using ordinary pliers the pressure tends to bias to one side and can sometimes break the wire. Proper Scotch lock pliers close evenly and can't close any further than the thickness of the lock. From memory, we were ok to use them on all vehicles apart from Mercedes as far as warranty was concerned. Later vehicles with by-pass relays were connected in a slightly different way using a telephone type push together connector. but even this type of connection breaks into the insulation and grips the core in a fork, much the same as a scotch lock really.

Having said all that, I would only ever use them for tow bar electrics, never for accessories unless linking in the feed to a relay.

Scotch locks provide no protection from water ingress, copper oxidation and do not provide a full surface area clamping solution. Also once they have been closed...how do you actually know you have a sound connection?

They are, and always will be a lazy solution to a problem that can be done properly with decent equipment and parts.

-

As soon as everything arrives Ill get some work done and give an update because its been far too long!. Think I might be suffering from some of those mid project blues that have been mentioned

Jad

I know exactly what you mean!!

-

No amount of additive will do anything to solve your problem.

Diesel goes straight into the combustion chamber, not the inlet manifold. The 'gunge' as your mechanic puts it is either a very slow oil leak past the turbo (normal on floating bearings) or oil / contaminated oil from the crankcase breather. I'm not sure on the freelander but most have a PCV valve on the cylinder head which can become faulty and let through excessive crankcase gasses through the breather arrangement.

Either way, what you describe sounds normal.

-

Sounds good.

Stupid thing is, I started this post, have done the conversion...but I don't remember what parts I ended up using! haha

-

I know the theory is good, but sticking a little coil of wire in a hole to hold a brake caliper on just sounds iffy!

But as its common practice, rather than drilling and tapping for a larger bolt, I'm happy to give it a go!

Are the caliper bolts M12? What length coil insert would I need?

No need to worry about helicoils, they are often stronger than simply using the parent material, especially with cast metal and ally etc. Think about stud and nuts...that is almost identical to a helicoil, it removes all torsional strain from the parent material, leaving purely a tensional force. with the helicoil taking the torsional friction force.

-

2.5" is fine on any TDI... All science aside...it's not exactly a powerful high performance engine even if you do shove a VNT and thousands of pounds of kit on it! 3" is just plain overkill, it'll just be louder you won't get any gains.

I run 2.5" on a 110 with no silencers and smooth large radius mandrel bends,

I had a bodged straight through TD system before and if you were cruising along you could not hear it inside, only if you put the window down and floored it. But it was messy and it did suffer for it.

-

Just went through this recently. (Information from National Windscreen)

2 terminal screens are pre 2002 and are single zone (positive and negative do not matter)

3 terminal screens are post 2002 and dual zone (negative in the centre...but would also work the other way round)

Have a 3 terminal sitting in mine now.

-

I put a layer of bitumen tape onto my tub, then a layer of tiger seal then riveted the cappings on. Can't say I'm worried about them being hard to get off, last ones lasted 25 years of abuse... Far future me can worry about that problem

-

You don't need them, purely extra protection

-

Sorry bit vague! I changed back for the reasons you described, uphill grunt and towing. I've also uprated the intercooler to help it out as I will often have reasonable loads in the car.

All depends what you want to do with your car. If it's a all rounder, off roading / towing / load carrying / kids to school. Then you can't beat the 1.4. But if it's more for a bit of fun, off roading and motorway then the 1.2 will be better.

-

I changed mine for a 1.2...then realised land rover got it right at the factory and put the 1.4 back in!

-

Personally I would give that exhaust back to them.

The TD exhaust is 2" not sure what the 200tdi is as standard. I made my own exhaust for mine (200 with 300turbo) in mandrel bent 2.5" pipe using bolt together fittings...cost alot less than £300, will never hit the ground, is totally free-flowing and has a anti-vibration unit. You could probably do it cheaper still

-

Re the point about Alarms...yes lots of people ignore them, but considering how many defenders don't have one. If you do and a thief sets it off they might think '**** it...won't bother, I'll get the other one down the road'. If they try anything outside in the dark...Least you will hear it, just don't rely on a factory fitted alarm, they will know exactly how to counter that...retrofitted ones down by yourself and not by a firm are the best option.

Trackers however are not a bad shout. I'm not as worried about things like doors, they can be replaced, the whole thing can't! A determined professional thief will get your defender...But can you get it back?

-

Check the condition of the vac pipe (they perish) and the clips that secure the vac pipe (they are typically the old wire type, swap for a jubilee). The sound is air being sucked through a crack or under a hose tail at one of the ends, the sound is always there if it leaks, you can only hear it once the engine is off.

Chances are that'll be it, next check is the fitting at the servo, I've not had one out before but it's a clip in fitting, presumably with a O-ring at the base.

-

Those don't sound right quite right.

Purple/Brown for instance is RKB101111 and is a HD progressive spring fitted to both sides. Green White NRC9449 is a standard Spring.

Your yellow/white NRC9449 spring should also be accompanied by Red/Blue NRC9448.

Sounds a bit pick and mix. Best bet is to look on microcat or lrparts.ru for instance and do a little digging.

-

I've done it as well, parts are cheap and easy to make up yourself. I used 30 degree banjos on the calipers and swivel fittings on the centre T piece.

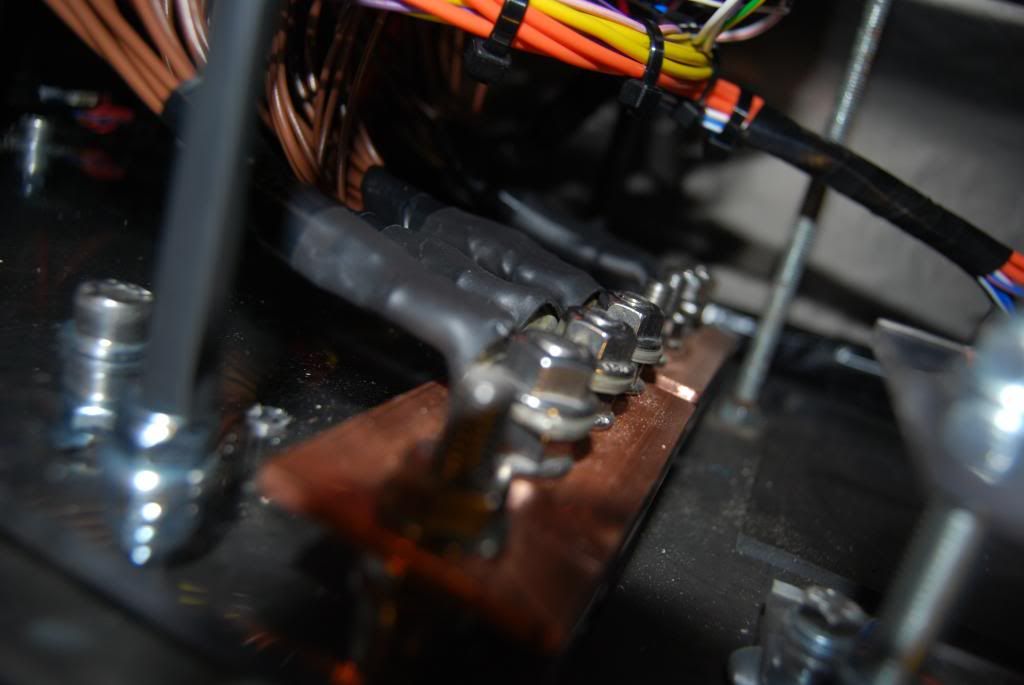

Pic before I painted the axle and tidied it all up

-

It's not the rings that go but the pistons themselves - they crack right across and through the crowns. The head also cracks between the valves in each cylinder. The 12J was a very robust engine, but it just wasn't up to a cheap lash-up of bolting on a turbo - the compression ratio was too high, which is part of the reason for the cracking. A tdi has 19:1 CR, but the 12 and 19Js have 23:1. The metalurgy wasn't right either. I know from personal experience - I've had two of these engines and have seen several others with the same failures.

Fair enough, I'm going partly by what I've heard from other users and the fact we ran one for 250'000 miles and changed the rings twice.

Converting to rear discs on a 110

in Defender Forum (1983 - 2016)

Posted

Massive improvement, especially when towing....but then my rear drums were not working!

Drums in theory are better than discs when you consider force in to force out. But they suck at dissipating heat, need adjusting, get clogged up with mud, pain to work on etc etc