roachy

-

Posts

86 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Posts posted by roachy

-

-

Im hoping for a bit of help please?

My truck has been gradually losing power and has now got to the point where it struggles to climb over a house brick with 35"simex's. For a while its been struggling to do anymore than 50mph on the road and slows on hills.

The engine was rebuilt by turner's approx 20000miles ago so should be strong, there's no smoke and its boosting well so its gotta be fuel. Ive removed the pickup strainer in the tank and fitted a new fuel filter, the lift pump is nearly new and it filled the filter up in no time so no probs there. It starts and runs well so i dont think the timing is out. Im thinking its got to be the FIP or injectors? anyone got any different ideas or know how to check these?

thanks in advance

-

i recently got one of these off ebay around £200, (different seller). It's the best tool i ever bought!!! i spent 3 days cutting and welding 1/4" plate (30amps 40psi, so not flat out!) and it never missed a beat, its awesome!! No more ****ing Cutting discs!!!

-

Right from a local 4x4 breakers iv managed to locate and buy for £420 all the 200tdi parts i will need for the auto conversion.

Does this include the boxes? surely you could get an mot failed 300tdi auto disco for sub £500? then you've got everything needed plus loads of spares.

-

in that case, in addition to the one ^^^^^^

here on LRDirect but not at 79 quid plus vat/post

or

Britcar but still over 50 quid

you see my problem. thats stupid money for something so simple.

-

on second thoughts has anyone got one? LR want £55 for one so a secondhand one would be great, otherwise i'll have to make one.

-

lol, will do cheers mate

-

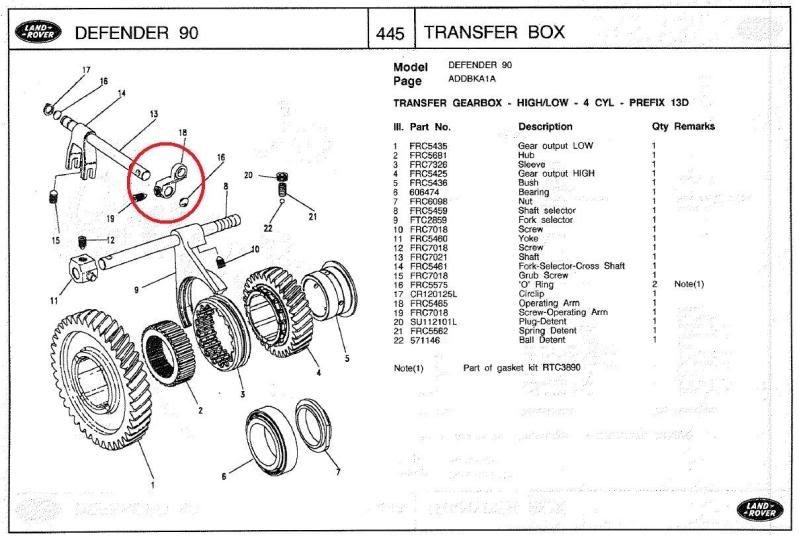

no, its the defender TB going back in, the disco one was like pic 2, afaik its the original 1984 box.

-

cheers guys, its item 18 in the first pic. will get that ordered tomorrow.

The wealth of infomation on this forum is ammazing!!!

-

nearly, last diagram item 10 is the bit in my hand in the pic. i need the bit that attaches that to the selector, mabey it comes with the box??

-

There seems to be a bit missing from this big meccano set i like to call my 90. I'm in the process for putting my defender tx box back in as i was using a disco one. i seem to have misplaced the bit between the selector and the bit in my hand (see pic) and i cant even remember what it looks like, does anyone have a pic of one or know where i might be able to get one? or does anyone have one sitting on a shelf gathering dust?

i tried using the one off the disco box but it has a different selector, so i thought i'll swap selectors over only to find they have different types of fork, so i thought i'd swap forks over only to find the grub screw location hole is in the wrong place! why do they change these things!!

Any help much appreciated

-

how quick do you need it mate, i may have a spare in the garage, im at work till 10 tonight, ill look tomorrow and if i have one ill stick it in the post for ya.

-

these are the guy's lrsengineering they're just up the road from me.

was a black top half dash with aluminium face?

-

i just had one made up at billing at a plate stall. will probably be available at LRO peterborough if your going?

-

battery drill? battery grinder?

could you get 14v and use jump leads? lol

-

please elaborate, i have a set of these that are leaking after 4 uses. do you have a contact number or e-mail?

any help appreciated.

the numbers stamped on mine are

92656

OE12096

and C249A3

-

Nice to hear someone has experimented with that method and i presume it is still plenty strong enough. I have already put the 200tdi backplate on and am waiting on a new seal. Im not in huge rush so i dont mind, it also means im leaving everything standard etc.

A drill and a file? Long and hard job then!! Thats what plasmas are for!!!

Chris

Yeah still plenty strong enough, it wasn't that hard a job really, just annoying as i was a toolroom tech for a few years so i know how easy it could have been on the old CNC mill. i've still got that backplate in the garage if you want it coz i've gone Auto now?

-

chrism, i had this issue not so long ago, i thought that as Land Rover invested in changing the crank seal for the 300tdi then it was probably worth keeping so i did exactly what you suggested and cut the D shape out. pics here clicky

i just drilled loads of holes then joined them up with a file.

-

cheers for the help guys, Al i think thats the best idea, ill take some off cuts into work and have a play, ill get some pics up when it's all done.

thanks again.

-

i can tig stainless well, just asking the differences with doing mild?

-

cheers guys, thats perfect, got some 2.4mm rods coming tomorrow, what sort of current am i going to be needing to get the penetration? my welder tends to blow a 13amp fuse with anything over 90-95 amps, so normally switch to 415 above that.

also i haven't done alot of mild tigging, 98% of welding i do is stainless. I assume it's just the same? just needs a bit more heat?

-

hey guys, i got myself a truck cab roll cage from billing today with the good intentions of migging it, however i've realised that to get a better looking weld i may aswell borrow my tig welder from work and use that.

here's the problem, i have only got 316grade stainless filler rods, if i remember correctly stainless is weaker than steel therefor wont be any good protecting me from death as i plummet down a steep hill? please correct me if im wrong?

does anyone know what grade rods would be best suited for this application?

i have some old steel rods left over from the days of gas welding but i'm not sure of the grade and dont think i have enough of them anyway.

or do you think i'm being too poncy and should just blast it with the mig?

thanks in advance for any advice ;-)

-

lol, very good!

that hammer is nowhere near big enough.

-

As above, that seems like a particularly difficult way of doing things! just move engine forwards.

When i fitted my 300tdi auto i mounted the gearbox and transfer box while leaving the engine on the crane, got it to the right place, tacked the engine mounts in place, then removed the engine and fully welded the mounts.

Simple, no changing props etc.

-

Yeah its ok. Not hugely challanging but a laugh still...

LOL, we still manage to get stuck nearly every time we go!!

300tdi no power

in Defender Forum (1983 - 2016)

Posted

Thanks, ill check this in the morning, would a blocked leak off pipe cause these symptoms though?