Jamie_grieve

-

Posts

465 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Events

Gallery

Blogs

Posts posted by Jamie_grieve

-

-

Bill, I'm really interested in your crawler box idea.

How exactly did you make it happen and how robust would it be compared to an LT95 or LT230 transfer case?

How would you proceed if the ingredients were a regular LT95 in the shed and a couple of spare good overdrives for it to potentially chop up and could lay my hands on a chain driven Borg warner transfer box from a range rover quite easily. I've also got a short LT77s laying around and a couple of LT 230's as well. I also have a couple of PTO units for both LT95 and LT230 with overload clutches on them as well which would be available to get incorporated too if I could suss it out.

I'm looking at sticking it on a GM 6.2 V8.

I've got a wee Myford type lathe but have never tried to cut any splines with it. Any tips or suggestions gratefully received!!Regarding the removal of the LT95 despite being a bit of a pain I reckon you'd still be able to do it standing on your head. I doubt you're that decrepit just yet!!

I think the LT95 is more suited to desert repairs than any of the other transmissions and could function longer with e bodge due to lower stressed components. It could be removed by using the winch and roof rack / roll cage with ratchet straps and the normal stuff I expect you carry with you. if no sunroof then the tops of the doors are stronger than you'd think with a board across them. A couple of pre prepared mounts for the job might be handy. My back surgery makes me think about preparing stuff like this more and more.

The way the mounts are on the chassis it will come out fairly easily downwards if you take off the fan to let the engine drop back and will lift straight back in between the rails using ratchet straps or whatever. The balance point is right at the front of the transfer case where it's really easy to lift it and lifting with two ratchet straps lets you rotate it to line it back up and one to pull it forwards into the clutch. I've never had much joy with jacks doing gearboxes in the field preferring to use as long a rope or whatever as I can to take the weight and allow maximum manoeuvrability for pushing, pulling, wiggling etc. I'm sure with your experience I'm teaching you to 'suck eggs' here. I'd have every confidence you'd change an eaton roadranger in your sleep with your boot laces and a bit of No 8 wire

Myself and one other lad removed the gearbox from a Werewolf armoured vehicle using only ratchet straps and a combination of prop shafts and half shafts as levers and rollers and anchor points. We only had to remove it and not rebuild it thankfully but it was fun looking back at it. Dunno if desert heat where the tools burn you or winter cold where they stick to you is worse?

I think Wildfing 1should be left alone and build something else. If not for my daft sentimental reasons at least for using as a qualitative and quantitative benchmark to compare the next vehicle(s) to. -

As a backup to whichever main GPS system is employed an app for your smart phone called MotionX GPS is hard to beat.

It can cache maps, record or export tracks and waypoints , send GPX files be text or e-mail, automatically post position updated to Facebook and uses either open source, Google or Bing maps. It is easy to change between coordinate systems. It's also only a few taps to find distances to waypoints, distances between two points without having to create waypoints and suchlike. The touch screen makes it all a bit more useful in real life and it's not difficult to waterproof a smart phone.

Modern smart phones such s iPhone 4s onwards and newer Samsungs have late generation chips which also use the Russian Glonass system giving vastly improved coverage and acquisition times. It's a very intuitive interface and well worth a punt for 69p or whatever an app costs these days.

I was getting better coverage in a concrete building in Iraq with my phone than I was with my Garmin GPS last year. The open source nature of the mapping meant I could download a complete street map of Kabul back when it was restricted or not available on Google. There must be a lot less satellites over the UK as the acquisition times here are longer than in the middle East for some reason. -

If any one has any further comments they wish add or have any inclination on the next steps I need take that would be most helpful Tom

I remember there was a charity called Rainbow Rovers who used Land Rovers in a fairly high profile manner some years ago. I wonder if getting in touch with them and picking their brains might be a useful thing to do? They are no longer operating I don't think so I doubt you'd be stepping on anybodies toes.

What type of traveling have you done until now?

Would organising a few smaller fund raising events closer to home give you a bit of 'past performance' and credibility before going for the big one?

Team Chaos seem like a good bunch heading in the right direction. Maybe you could get involved there and do a bit and as you help out I'm sure you'd learn a few tricks as well.

Raising awareness and raising money are two different things. Raising money is what makes things happen, raising awareness just reminds people of bad stuff that happens but has no connection at all with opening their wallets.

Don't let us put you off either, don't let us dampen your spirits if you want to crack on but I think you'll find there is a lot of good impartial advice to come out of this forum.

-

On my last trip I noted that most guys working in garages have no welding visors or eye protection and just squint when doing weld repairs, they can't afford them. On my next trip I'll get a bunch of visor lenses and pop one into small workshops I pass, just a little thing between me and them but might save someone from going blind and a nice excuse to stop and have a chat. Lots of little things like that you can do.

That is awesome, most people wouldn't even notice that. You're so right though. I often use those guys you talk about and employ local welders as well. It's hard to get them to use safety equipment of any kind.

You're also right with the lenses too as they often just use a lens or a bit of one in their hand.

I've got a goofy picture of a young lad who gas welded up the filter housing on one of our Kamaz and I gave him my Caterpillar safety glasses after watching him welding squinting through the sparks. A while later he came round to check up to see how we were getting on with the most amazingly decorated pushbike I've ever seen in my life. The glasses just added to his image, I did wonder if he ever used them for gas welding though.

I gave away plastic flutes on my travels, I made them out of plumbing pipe. They went down quite well but kinda had to be a time and place for it. The welding lenses is a great idea!

-

The two big players in the UK are both horrible to deal with, hate people and hate the equipment they sell. If you buy at a tender or auction you'll be lucky to get the vehicle you thought you were. They are only interested in how much money they can make from you and nothing else. They pretend to be a bit nicer if you're a fleet customer but they'll still shaft you if they think they can get away with it. I received a powershift transmission from one of them that was full of chunks of metal and knackered. They knew where it was going and knew it would be stuck in customs long after any warranty would have expired. They do it because they can and they know you'll be back next week because there's nowhere else to get some kit.

You might be lucky to find something good but don't expect a bargain. These guys aren't stupid and know what things are worth. They're very careful not to flood the market with anything to keep the prices high too. You can find better deals privately if you just need a Land Rover. -

Sounds like a fun thing to do. I feel your enthusiasm and excitement. However, playing a bit of devils advocate here:

My first thoughts would be your motivation. It could sound to the cynical like you're trying to jump on the charity bandwagon to finance your dream trip. Why would the donor community fund someone to drive roads that for you may be a great adventure but for those who live there are simply how they get around, such as going to work or hospital?

Why not use your collective skills and expertise to help a charity directly? The considerable amount of money it would take to buy, kit and support two Defenders, then fuel them and travel round the world would be better spent helping the charities surely? Not to mention the time it would take to do so the charity probably wouldn't receive cleared funds for years after you left. If for example you were to die of a snake bite in Jabrovia and the mission is aborted would the money used to fund the trip not have been completely wasted?

Why even take vehicles? How much use is a Defender trying to follow an Ural or Kamaz on the road of bones to a charity anyway? It's also kinda been done as well. Why not save the cash and use public transport, hitch hiking etc for a low impact mission.The point I'm trying to make (maybe badly) is that the donor funds required to finance to trip to get more donor funding for the charity would be better spent on the charity in the first place. Something even more silly and cheaper might generate more interest?

-

Probably quite a sensible move to go with the Ashcroft box and being a stumpy R380 we expect to be reading about an engine conversion soon I suppose now it can handle a bit more power!!

I had the misfortune to receive a supposedly good replacement powershift gearbox for a Hydrema from a well known UK military surplus supplier just like Withams. They knew it would be 6 months in Angolan customs and any warranty well used up. When I eventually got it and drained the oil it was full of lumps of metal and a lovely golden colour of phosphor bronze floating on top. I think you saved yourself a lot of hassle getting that box. -

Thanks for the info, my 110 is a 2.5 NA Diesel (Tithonus from Withams) its LHD and yes its b.Hot here, so my thought is anything I can do to help is worth it. It only had 1500 K on it from new but the original G.Box went bad pretty quickly once she started getting used for real, hence the change to the Stumpy R380

Your gearbox shouldn't have gone bad that quickly, especially with a 2.5NA in front of it.

One common mistake made with new owners of Land Rovers with manual transmissions is that all of them with centre diffs in the transfer case don't take gear oil in the gearbox. That includes the LT77 variants of which the R380 is one.

We used ATF or hydraulic oil at a pinch in our fleets of 110's operating in Angola where it gets hot too. Out of around 120 mostly 300tdi but also a few N/A 110's we had maybe 4 gearbox changes over a three year period and the vehicles were used proper hard. Many were armoured and most had cracked chassis and bulkheads at some time in their lives to give some idea of the abuse they took. Most Land Rover gearbox faliures in my experience are due to improper maintenance and water ingress. The standard clutch will slip before anything breaks in the 'box unless it's worn or been run with gear oil.

Check the splines on the input gear on your transfer case if it's an early one to make sure it is the newer type of gear fitted or the splines will wear quite quickly.

Make sure you treat it to a heavy duty clutch fork when the box is out as the original is made of cheese and not fit for purpose. If you weren't made aware of this before hand and even if the box is back in I would take it back out and change the fork for a good one if you need it to work hard.

Good luck and have fun with it!

-

Have you any idea of the shaft diameter and spline count of that Mitsi rear output?

I'd guess that most DIY types could get a hold of a lathe easily enough but cutting internal splines is hard for most of us. Could you match that spline to a CV joint inner which could be turned and made to fit in the gear?

I notice that Mitsubishi shafts are often 25 spline which coincidentally is the same number as the splines in my portal diffs. I've been unable to find any diameters anywhere yet.

-

O´Téunico: I'm jealous of your computer skills, I'd have no idea where to even start manipulating pictures like that. I've given up on Photoshop before I even got started on it.

I cant really think of any realistic way to make a doubler out of LT230's either but did wonder with your skills of computer graphics if you would come up with something wonderful I hadn't thought of. Even getting a huge pile of them and just using the high and low speed gears I still can't really see a useful way forward. The configuration's wrong really. The LT230 is a good strong transfer case with the centre diff and better low gear reduction than any other off the shelf case I can think of but because the reduction isn't available in line with the main shaft it just doesn't lend itself. I don't know if any parts from the LT95 are compatible as it has high and low range at the PTO so a conventional doubler would be possible with it in front but without an overdrive gear possibility and only four speeds it wouldn't satisfy many peoples needs.

An epicyclic reduction as Bill did makes a huge amount of sense. Huge reduction, strong and compact.

The splitter box as above would be good on many trucks but I can't see the LT77 and variants as being strong enough to handle at least double the input torque as would be expected of a doubler as opposed to a splitter for a half gear for towing or whatever..

I think your Mitsi idea is completely viable but only question if the overall reduction ratio and the extra length could be more easily obtained using off the shelf parts?

-

Now that you've lost the ability to have a Viking winch, ( it is a vapour build so no restrictions need apply

) I'd suggest that you should now look for an alternative transmission. The Mitsi setup you have here is very long, using 4 cylinder Defender or Santana components and a Rakeway short rear housing you could get a Land Rover based tranny down to around 29 1/2" or 79ish cm. If you sliced a couple of LT230's down the middle and made some photo shop of the intermediate gears what kind of tranny could you build us then?

) I'd suggest that you should now look for an alternative transmission. The Mitsi setup you have here is very long, using 4 cylinder Defender or Santana components and a Rakeway short rear housing you could get a Land Rover based tranny down to around 29 1/2" or 79ish cm. If you sliced a couple of LT230's down the middle and made some photo shop of the intermediate gears what kind of tranny could you build us then?FTC5090 is the coupler you need from the auto to the LT230 which is probably the thing you'd modify putting something else on.

Edited to add:

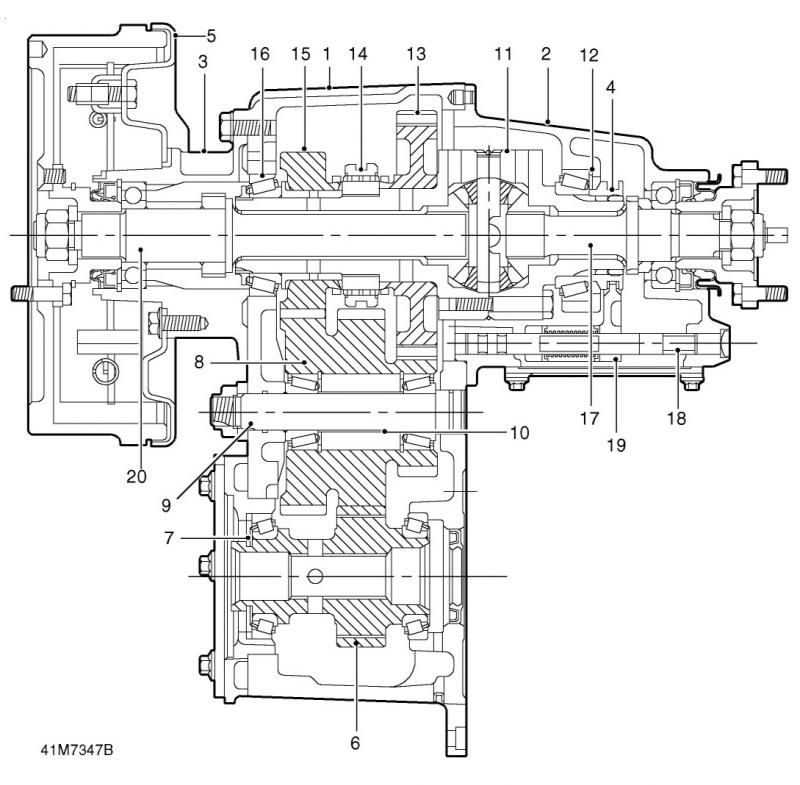

This drawing from Rave of the LT 230 might come in handy for your scheming and photoshopping..?

-

I seem to remember an inertia switch thing too, it cuts power to the pump. It was ages ago I had all this but it's coming back to me. I used a nibbler to cut the hole out the floor as the hoses and wires are right underneath but to be fair a grinder would do fine as long as you don't go daft.

-

I'm planning on re running it to a new inline pump.

That on it's own'll no dae.

The fact that you have bubbles in the line means the pump has probably failed if the spill pipes are good and no leaks from the injection pump.

You'll be trying to suck fuel through the original pump filter which is probably blocked and sucked itself into the pump and through the valves that are there too. The cutting the hole in the floor isn't a big job.

You bridged the fuel pump relay yet? That's where the other end of the wire is you're looking for to energise the pump

You measure how much fuel comes out in a minute to see if the pump's working or not. I got like 120ml and changed it and no dramas after. The spec was 180ml I think.

-

Engineering company has said NO to the "VikingWinch". Any winch can be approved as long as it has CE certificate

, and a home made one will certainly not

, and a home made one will certainly notWhy would the winch have to be approved? If it wasn't being used for hire or reward you can carry as much scrap iron as you want on your truck and if it happens to be bolted down to stop it falling off and as your preferred method of carrying it I don't see how they could say much unless it had projections not compatible with pedestrian safety?

Have you got any links to any good photoshop tutorials? I got a copy of Photoshop CS4 now and a thing called adobe bridge and I cant make any sense of anything at all. The whole thing's a complete mystery to me but I quite fancy a bit of vapour building while my back heals up. I use a Mac if it makes a difference.

I've got a bunch of ideas and drawings on paper but I think being able to show them to others would be fun and Photoshop seems to be the way forward. Even changing the colour of something would be cool.

-

I'd check it's not the relay by bridging it with a bit of wire then seeing if you can hear the pump and see the fuel move.

Check your spill pipes too, although there'd be a leak.

I'd also suggest if you do need to replace the pump then it won't be the last time you're in there and to aid future diagnostics I'd recommend the 'cutting a hole' approach. The carpet's really thick and makes the 'repair' more or less invisible.

-

There's not much not to work really, you can take the pins out and take it apart and clean and lube it and it'll be fine.

Take any corrosion off any sliding surfaces and maybe stick an inner valve spring in where the vertical spring goes to make it more reliable in the mud,

-

For example, a difflock cannot be made road legal because regulation is not clear about it

Hard to understand why when some vehicles are fitted as standard with them.

Move over here and bring your weather when you come

-

Those 'cut to fit' axle shafts also totally lend themselves to folks making their own difflocks from machining dogs on the back of extra spider gears and sliding them up and down to lock the diff.

-

I love the proportions and look of Jeeps. Really interesting build this.

How are you notching your tubes?

-

The four cylinder LT77 with short bellhousing and Milner adapter as Gremlin says above is what I would say too, this gives a total length of 32" from front of adapter to rear of hand brake drum.

This can be shortened by nearly 3" with a Rakeway short rear shaft and housing.

813mm and 70mm for the Metrics amongst us.

Hope that's of some help.

I have Santana axles and discs on mine, not much help maybe but if you want something measured let me know.

-

I Think the reduction is in the wheel hub, that is the way we have it in these machines..

http://komatsuforest.com/default.aspx?id=84551

The rear hub is missing at the picture from Angola

The wheel hubs don't have any reduction in them like the forwarder in your picture but one other interesting thing is the pipe joining all three sections is to provide positive air pressure to prevent the ingress of dust and water. Sometimes the regulator fails and oil blows out of the damaged seals.

I see you are a leaf sprung enthusiast

What do you think I should do with the old Stage one?

-

same Ploppy Plop Plops anyone

I love the swear filter on here!!!!. I didn't even realise my language was so carp carp **** turd until I read that.

Your list of ingredients suggest that due to unsprung mass, whatever you build would have more in common with a 4wd tractor than a European spec comp vehicle, so you might as well go as wild as your imagination runs, providing you have ready and regular access to terrain where you can fully exploit your vehicles abilities.You're exactly right, Whatever shifts this lot is probably gonna have a 6BT Cummins and I've this notion of building a monocoque. The tyres are 16.00 x 20. I'm very lucky with regards to access to terrain and project 'B' the LWB Renault transporter will help with additional play grounds further afield.

One of my problems is between the Praga and the Volvo they just out everything the Land Rover so many times over in every kind of terrain and they're the daily drivers!

The Land Rover as the 'toy' is the least capable and does need reinvented. I could fairly quickly finish it as is and have a quite uncompetitive challenge type motor that's mostly reliable and could be kind of entertaining. The second winch could work off the same PTO with use of the free spool levers but would just be a bit of a disaster in any kind of competition but would be handy as a wee road motor pulling old carp onto the trailer.The leaf front suspension is dreadful but still better than dragging a track rod hanging below the axle through the tree stumps that surround the house and has more travel than a standard coiler. With the engine so far back there's plenty room for four links and a transverse leaf spring.. Or not.

Hmmmm, dunno what to do.....

WARNING:

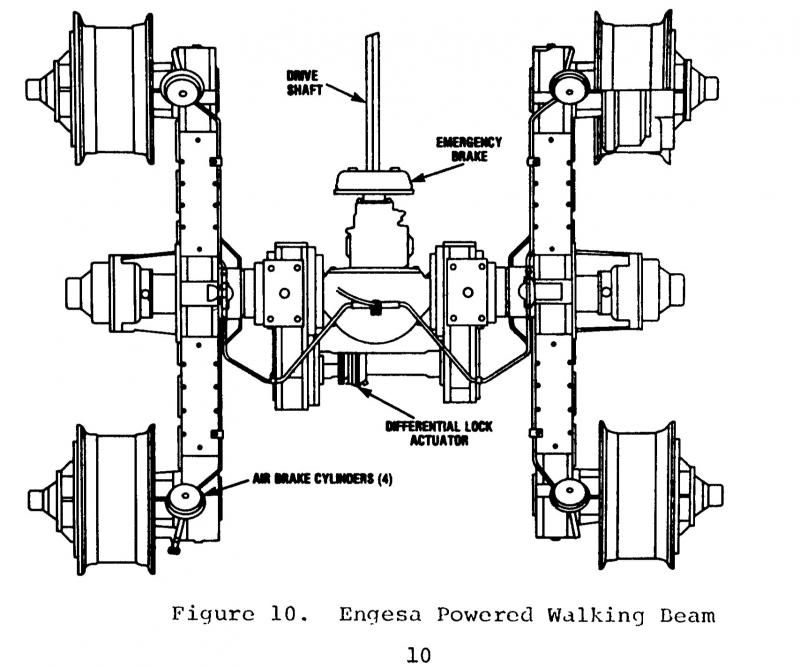

For those not interested in Engesa 25's please look away now.PS, photos of the inside of the Engasa walking beam would be interesting, as I would be interested in knowing if they incorporate a planetary reduction unit concentric with the pivot.

For those not interested in Engesa 25's please look away now.PS, photos of the inside of the Engasa walking beam would be interesting, as I would be interested in knowing if they incorporate a planetary reduction unit concentric with the pivot.Bill, sorry, when I said

I've got photos somewhere of inside the walking beam.I really thought I did, maybe I don't after all. The only ones I can find are from one we cleared on a mined road in Angola:

I don't recall their being a planetary gearset in there, I think there would be some reduction as not all gears are the same size but I wouldn't like to guess how much. I'd say these trucks are really strong and well made. Loads of them laying around in Angola. Maybe possible to guess from the spacing between the gears on a better example than this one.

-

There heavy!!!!!

LOL, kinda are though but would hopefully keep the wheels pointing down most of the time.

That weight is for the fronts, I think the rears are about 50 Kg's lighter. I would like to weigh them myself somehow just to know.

Same with the GMC 6.2. I've seen weights around the 300Kg mark for it but not sure. It is tiny and it is quite light.

Getting one of these in the post in the next few weeks if all goes according to plan:

You can add a Praga V3s portal axle weighs 332Kg.

Same stud pattern as the TRM which is handy for me.

-

I would like to continue it but can't seem to find a direction to go in.

I'll write down the ingredients I already have in the shed apart from what's on the motor already:

2 x LR PTO winches + 1 x Heavy PTO winch.

3 x ZF S5 24 gearboxes, 6.35: 1 first gear, SAE 3, one with hydraulic PTO. 1 x LT77S with short bell housing and Milner V8 adapter plate

3 x Rockwell portal axles, 2 rears, one steer.

3 x rockwell transfer cases, one with rear facing PTO.

1 x LT 230 with PTO for front winch,

1 x LT 95 overdrive

That's the 'goodies', in addition to that, probably the same carp anyone who's been into Landies for years would probably have laying around.

With all that history and time you've put into it I say keep it as is and build something more "extreme" and with those so fashionable coils, for challenging.I think after all this I'd rather gouge my own eyes out with a wooden spoon than put coils on!!

I hate the way the steering rods and track rod is on them. I've been left high and dry a few times and seen it on others plenty too.

Why they would design an off road vehicle with the track rod hanging below the axle I will never know but it's common on most 4x4 / 6x6 trucks too.

I was thinking of just finishing it as a road motor then using the parts above to build something else, maybe a monocoque with independent suspension.

I don't know how I'd go about putting it on the road again as there's not much original left. I keep Sorning it but really don't know how that's gonna work either when the thing that's sorned keeps changing.

Keep the suggestions coming please!!

axle strength....

in International Forum

Posted

I'd say you'd be better to use Toyota stuff especially as it's easier to get in NZ than Rover stuff and if you're at an event and break a C.V you've got more chance of finding someone with a spare Toyota C.V than a Rover one. Without spending money on Ashcroft or KAM or some other aftermarket shaft there's no way a Rover front axle can handle 35's reliably with the power you'll put through them at club events unless you rethink your power plant and drop in a N/A diesel or a 2 1/4 petrol instead.

The rear's are quick enough to change and should last for a while. Sticking in 24 spline parts isn't worth the hassle and in fact depending on the year and whether India was making steel from old toasters or washing machines and if it's OE then a ten spline can even be stronger.

Just to back up where I'm coming from (not just because I've run fleets of Land Rovers and Toyotas for a living) looking at the graphs below stolen from Ashcroft's site and also good info in the KAM link below you'll see that the yield strength of both front or rear shafts is around 3000ft lbs or just over 4000Nm if you're metric. the overall reduction using your LT95 is 48 : 1 which would let you have a maximum 62.5ft lbs of torque from your engine if a wheel had lots of grip. Normally the torque is distributed between more than one wheel but with a locker it can happen. A smaller tyre will normally spin out and break traction before the shaft will break but when you start running bigger grippy tyres with lockers there just isn't any margins left in the original parts designed for a 1600cc Rover back in the day.

I think Toyota half shafts are good or about 4500 or 5000ft lbs but not sure, lots more than the Rover anyway and stuff like brakes and bearings are easier to find. I'd use Land Cruiser axles rather than Hilux to avoid having a centred rear diff and an offset front to drag two ruts through the mud and bounce of the crown between deep ruts. Offset diffs are better.

If you do use the 10 spline stuff it would probably be mostly fine with an auto and a sympathetic driving style.

http://www.noposer.com/wp-content/uploads/2013/01/Guida-alle-applicazioni-KAM.pdf