Stevie D

-

Posts

309 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Posts posted by Stevie D

-

-

As the title says what's the best fluid / solvent for a small machine mart parts washer, I can get my hands on keytone / toluene etc but am wary of using that in the washer with the flamabiltiy risk - I'm probably going to get some kerosene as that's got a much better flash point. Rtied to get some gunk but that's very expensive. there's a few new 'environmentally friendly' solvents about but these are even more expensive.

I want to clean swivels, cv's etc so whatever I use isn't going to stay to clean for long.

The local dump takes waste oil etc so proper disposal isn't an issue.

What are you guys using?

Thanks Steve

-

Iain, just slacken them all off and lift the body an inch or so one side at at time or one end at a time whichever suits best, as Mav has said making sure it's properly supported - would give a nasty nip or loose a digit / big lumps of wood to spread the load, the ones really akward pair is the at the rear of the sills as i't difficult to get the long bolt out far enough. Oh - theyre an imperial size socket and spanner, but think from memory a 15mm suits. Oil them all first a few days before hand.

Igol, there's ten mounts, 5 down each side, 2 at the front at the radiator crossmember, next two under the footwells, at the back of the front inner guards, 2 on each sill, and two at the rear crossmember onder the back bumper.

Steve

-

-

Egr?

-

Rave says 50/50 - capacity is 11.5 litres

-

As above take off the cover and inspect input gear with a torch.Other sources of the drive train clunk are a bit easier - found most of my slack in the drive train was the rear shafts and drive members - easy enough to test - take off the rear dust caps and rock the truck forwards and backwards, look for slack at the splines, then move onto uj's and also the rear a frame bj.

Enjoy the new truck.

Steve

-

All depends on how badly rusted the body is - some of the chassis mounts may be non existant lol.

Think Dieseldog got most of them - the seat belt bolts to the chassis foiled me (front at the rear of the gbox tunnel, and under the rear boot floor - hand brake cable was the other.

Steve

-

'GDI' products seem to have a lot of stuff (seems like alot of the old SPI stuff and some more) - trading on ebay, but not sure where else - found some good looking panels for a disco

-

Slightly more hi tech solution (spayed onto tyres via a central pump / spray nozzle system) was on tomorrow's world many years ago - demo'd on an ice rink on a m2/3 ford fiesta or something. Suppose it's evolved from there lol...

-

On the plus side they're easy to install once the old ones are out, yjink the jury is out on the rest of the pro's and cons of polybushes?

-

Similar to the above I've had similar on the 110 csw with the rear 'a' frame - chassis bushes, not a pleasant experience.

Steve

-

As Simon says its not diffucult - I just slackened off the nearest ones and jacked up with the troley jack and a big lump of wood to spread the load a bit so I didn't dent my new sills - I was able to change the rear crosmemmer ones by using a big lumpof wood as a lever beteween chassis - I just bought new land rover ones off fleabay for a £1 each.

Steve

-

Did the same with the slide hammer and spanner - hot engine etc - eventually shifted. Some car wheel nuts / bolts are m14 x 1.5 hat's what I had handy

Steve

-

Similar issues with the skoda octavia - probably similar mc and abs, didn't have the software or cable, so had to prompt the abs pump to run on a gravel track to get the air out. I used a vacumn bleeder in combination with the pressure type to resolve it.

Steve

-

Wrong part of the country - and he doesn't state why it's a cat C but here you go http://www.ebay.co.uk/itm/LAND-ROVER-DISCOVERY-300-TDI-AUTOMATIC-1995-5-SEATER-IMPORT-/150964763630?pt=Automobiles_UK&hash=item2326337bee

-

They are the rubber spring isolater fitted to the back - as said the meatl ring is bonded to the rubber / plastic bit - metal ring corrodes and falls off.

Here they are...

http://www.paddockspares.com/anr2938-rear-spring-isolater-top-spring-seat-from-ja.html

ANR 2938

-

I've a spre of the bosch relay new in the box if anybody want's it, left over after I downgraded from the 110 csw to the disco :-(

Steve

-

Same engines as the defenders albeit with a few very mior tweeks like turbo lo0cation on the 200's. As mentioned above rust / rust & rust are the three things to look out for - take somebody with you that knows disco's or have a real googd read through the posts here before you part with your hard earned cash - it's often hard to find or in places hard to see, the biggest are boot floors, inner and outer sills, front and back inner wheel arches. Rear boot croosmember, in fact any of the body / chassis mounting points - there's ten of them. The rear end of the chassis sem to suffer from the main crossmember back so have a good look / hammer here too. Any seriuos rust here will be expensive to sort and render the truck an uneconomic repair if you can't do it yourself.

See if you can find either a sunroof free one or an import from the likes of Japan - these wo'nt have the as serious rust issues. Poverty spec ones won't have as many electrical gizmos to break.

Any mechanical issues are easily sorted.

I guess £1500 is realistic - althought early TD5's can be got for that sort of money too, however expect to pay potentially the same again sorting it if you get a lemon. Nice truck, better drive, but their own issues.

300tdi's stopped in around '98 so youl'll not have to worry about the big tax.

Have fun.

Steve

-

Nice work - love the atention to detail with the hinges.

Steve

-

Just replaced the sills with 'New' ones (already had the bits before I discovered the box section method) and now want to add some under body / side protection to to truck rather than putting the silly palstic bits back on!

Now the sliders on my 90 and my old 110 csw were chassis mounted - front outriggers and back, with an intermediate fixing on the 110, but I've seen a lot of 'Body' i.e. sill mounted, with a folded section of 3-4mm welded to the slider and slipped over the sills / drilled through and attached.

Which is better? I'd imagine the sill type might add another rust trap for the sills, but maybe stronger?

Any opinions - I've done a search but not really got an answer - or is it down to personal preferance?

Cheers Steve

-

Sorry Jason should have said my current road going truck is a 300tdi Disco so I need the individual parts.

Steve

-

Can this be done with the factory parts on a manual vehicle?

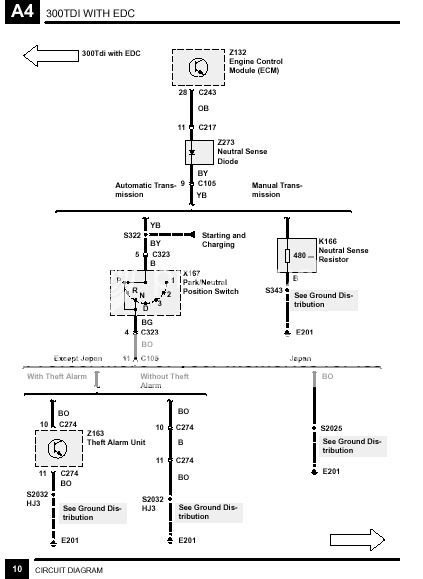

I was led to believe that it was only factory fitted to the auto's and had some interaction with the edc ecu? I've most of the factory parts gathered but never implemented. Time for a rethink now?

I've the steering wheel / controls, rotary coupling, ecu (the silver box AMR1173), just need some wiring (presume some it will already be there in the car - I know the pump etc is there under the bonnet), some vac hose, the vac break switch for the break pedal, some knowledge, the belows and pump - it fell off my workbeench and busted so went into the scarp pile lol...

Any advice welcome!

Cheers Steve ;-)

-

That should be fine get some 2mm plate and practise / optimise settings for good penetration etc for a few hours/ days with it in a vice or something (vertical) before tackling the chassis. As the guys have said go to the mig welding forum - some good guys there too will give you some machine specific advice.

Steve

-

It will affect your range ever so slightly by moving it lower. The DV 27 type wipe is old technology now - although it works very well there are the more compact tuned variety available now - possibly what you've seen in the us.

Steve

H1 HID spotlamp upgrades?

in International Forum

Posted

Anybody modified any standard halogen H1 fitted lamps?

I've a pair of Cibie Super Oscars that I feel would benifit. With the price of the kits now bavailable for around £20 on that popular auction site I was going to give it a go.

ARe the lamp units / bulbs a straight swop - or are modifications needed? I know the ballasts need to go somewhere.

Am I wasting my time and money - or is it a worthwilst job?

Cheers Steve.