-

Posts

1,606 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Events

Gallery

Blogs

Posts posted by Team Idris

-

-

The two pack lacquer gives it the shine on top of the mat 'colour'.

It can be put on with fine roller, but it is best sprayed. The two parts should be about right for thin-ness.

-

1972 and re-cycled, but still taking abuse

https://m.youtube.com/watch?v=SPFR3UJ1Go8

And the electric water pump is just brilliant! I am sure the main fan was kicking out during the day? How is that even possible with no natural air flow?

-

1

1

-

-

For the metallic blue van I used a mat blue and a two-pack lacquer. Both dry very quickly which is great. You can go a fair bit wrong and still sort it out. I think the clear can even be used as a sealer if you are over painting an old colour? Two-pack doesn't react to much.

-

It looks really good and I got the email. I even got a reply to my reply

Basically it wouldn't run right at work and I suspect too many work mates are using the Internet connection for radio

But could be graphics card?

-

Probably a typo, mig throws down less heat. I love TIG, but you have to throw in some pre-heat to start a weld pool.

-

I don't regret pulling my mains and heads to ARP toques, even though I was fully aware I was probably doubling the clamping force. I had concearns and it made my ring twitch. But at the end of the day I wanted these parts pulled down harder to stop the mains walking and to increase head gasket life.

Next time I would use rover torque settings and be happy that I was pulling more clamping force from the UNF thread. I think the honest truth is that; "you are the engine builder" when you buy aftermarket upgrades. I couldn't bring myself to condemn ARP any more than I could the billet-vernier duplex-sprocket guys, the max-torque cam, the dry sump pump or Craig Davis. When all said and done I own a machine manufactured by Steve Knight. I'm responsible for my own crazy party

-

That doesn't look right, but, how close is it to the other cam lobe? If it is slightly off set by a little bit then that is the bias to rotate the tappit and make the wear even across its face.

Unfortunately I can't tell you what the typical offset bias is on an engine.

-

That's the same fix I just did on my winch. Yours looks great !

First thing to note is that a helicioil doesn't spread the load like an insert does. Also the helicoil puts down some uneven forces as the thread tries to roll. Nut inserts don't do that, so that looks a cracking fix

The weld could be high silicon. This reduces the chance of the weld cracking, but it would have meant that helicoil number two was in softer metal?

If that doesn't do the job I'd keep drilling until I hit oil. Then I'd seal the thread.

I hate helicoils, but we use them a lot at work and they are better than bare ally, even if it high magnesium alloy.

-

Sounds like a reverse vortex coming off the front of the vehicle and working against the fans. Do the fans have a proper fan-cowl in the form of a box? (As opposed to two fans lying against the rads fins)?

Landys have funny air flows. At 30mph a sheet rolled up in front of the vents started moving toward the bonnet edge!

-

I did the same as House Of Flying Spanners on Petal and used bike gear change levers. I fancied the first4x4 kit, but I don't have air on board, so I decided against.

The basic design of mine was to drill and tap the old levers so we can easily revert to standard if the cable breaks. If you did that you could run standard air Rams? No need to strip the winch then

-

It would probably let go if you sat it on its back and filled the dirt seal gap with phosphoric acid. It penetrates and converts the rust.

I suspect that I actually would have picked up a welder and given it a few runs to shrink the piston? It's my weapon of choice for most jobs

-

I think the last one is in a blind hole. You would need a special puller thing I think?

Some talk of having to line bore or ream them after, but that seems unlikely. They are just weird because they are all different sizes?

I didn't bother doing them on mine because I do so little mileage, but it has to be worth doing to have a nice engine.

-

The flow is down to how much the pump moves per turn to give cc/rev.

After the pump is a flow control valve which kind of tries to sort stuff out, but not in a nice way.

Mercedes probably doubled the pressure so they could halve the flow and make all the parts smaller.

If you think hydro-assist might be good then you probably need even more flow, so merc might be going backward? But it really is down to that cc/Rev when you are low engine speeds.

I can't help but think that there ought to be a 3000psi valve that's slips into the column and sends oil to a steering ram, so that the PS box just becomes a manual, but I haven't seen such a thing. I also wondered what an electric flow booster pump 'teed' in would do?

-

I actually started doing pieces to camera back in the early 90's with the Triumph spitfire build, with dads video recorder. Now that the tech has become 'more' than a home movie I'm back at it with the IPad !

https://m.youtube.com/watch?v=H4fO692mzZs

Very pleased with my telescopic and electrical tape pointer

-

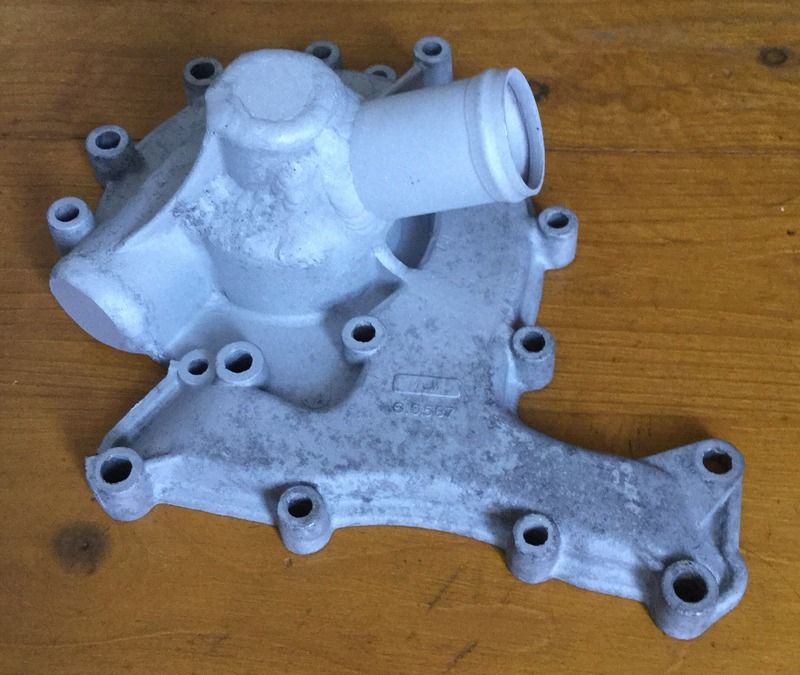

Normally the issue is finding one with a good oil pump housing?

I can't see it being an issue on cooling. Half of the pump is the water pump body? Mine was bad as has been okay off-road.

-

I find if it is the 4x4 (or the writing) that if I am right next to it I get interested and then start work. The hard part for me is just going 'to the job'.

Having the goal of an event in September helps.

There is also "the spark of an idea" that sets me off on some mission.....

-

It worked fine with their brown and bronze to make my S1 look lovely!

-

You can see on the sketch that yours use a casting port that is blocked off. Joined by a vertical channel that shows as raised metal on the body.

-

The 'return restrictors ' are in the return pipe. (I replaced mine with a sprung ball valve set to 4 psi). So it doesn't matter if the fuel enters left or right as they are just threaded 'T'.

I think you could block one and just feed 4-5psi! Return pipe seems a stupid idea that doesn't fix the issue of fuel boiling in the carbs.

The big plastic ports go to the rocker boxes. The 6mm next to them are the bowl breathers. I have one pipe on each of mine. They let some fuel out on really steep nose-downs. As long as the pipes clear the hot manifolds they are good.

-

-

That's good news because I could only think rakeway as they have a load of cnc gear, and it would take time to convince them to build some...

-

Yes, self latching relay. Take a normal relay and wire the output to the trigger so when it contacts it stays 'latched'. But where it is fed by a diode so it doesn't back feed the ignition wire. The thermo-switch then breaks the latch wire when it opens.

Thermo switches come in at range of temps and NO or NC (normally open / normally closed)

-

Well, mine works in the back, but I guess you plan for the worst with this set up. I have two 9 amp 14" sucking fans and a 3" deep ally air box so all the rad fins work equally. The box has a divider plate bit so one fan can still work if the other fails.

If your set up already has a good cowl/box then it must be a water flow issue?

-

Anti squealers do bias the piston one way. It's not the best way to fix the problem of high frequency chatter. If they don't squeal you don't need them.

2.25 Petrol idle problem Series 2a

in Series Forum

Posted

It does sound like dirt in a slow running jet?