-

Posts

1,606 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Events

Gallery

Blogs

Posts posted by Team Idris

-

-

Electric fires are 240 volt which is 20 times more than the car so a short length of resistance wire from one works at 12 volt. Put it in front of a fan and it's an instant demister. Good for cutting polystyrene as well

-

Swapping notes certainly helps. I don't know how it works, but it's maybe like a better understanding?

I had a bad turn in April where I got to Easter and just switched off. Then I started writing short stories and as I went about that I came accross a lot of folk who were having the same issues. I've been better than I have for a fair while, which isn't what I expected at all. So I've been going a bit further and that's been well recieved just like this thread has.

-

I butchered some old S3 ones for my project. A pop rivet gun and some hope made them okay

-

Second winch makes sence if David Bouyer has any Kingone units left at £400 each. That's a great rear winch. Lower quality, bigger, but pulls as good as the milemarker. ( better on mine, as my front overrun valve is toss).

I think drive-assist is more important backward because it's harder to choose a good driving line. Some winch challenge punches would be out of reach without it.

I was accused of promoting twin pumps

I think that was to get around the oil pressure being shared between front and rear winches? With both going you only have 1500psi each. But I can't hardly remember yesterday. Plus I have no more space for a second stage.

I'll add a strange bit of info. I did say this in a PM to Tobias, but I'll throw it into the open pit;

Some guys had an electric tipper pump which they said was for self righting. However, I suspect it was more subtle than that?

A gear pump is 90% efficient or better. That 10% is what gets past the gears + drag. Lets assume it is all internal leakage...

So you do 100 litre a min internally at 3000rpm and 3000 psi and the gap lets through 10 litre/min. That mechanical leakage gap is the same regardless of pump speed, so you still leak 10 litre/min at 1000rpm. But your 90 litre/min output flow is now 33.3 minus 10 litre min. Add in some wear and you can't do full pressure at 1300rpm !

Unless of course, you have a booster device which isn't engine speed derived, like a 12volt tipper motor pump. I haven't the weight left to add anything else and I'm willing to put half worn pumps back on the shelf every 3 years, but its a neat fix. +you can self right if you set the oil tank up right.

-

Engineers Perspective;

Looking into the future at new Diesel engines it is hard to fit particulate filters and converters to smaller vehicles. It's a simple case of packaging that will likely make smaller 'things' petrol/electric. (Or hydrogen).

-

Attention gained

You don't need two speed pumps if you use a hand operated spool valve. There is no need to go slow unless you are at the end of the rope or in a tricky spot. Then you can go as slow as you like any time you want.

The milemarker motor already runs well over max speed, but you aren't driving a conveyer belt for 3 years so the extra wear per revolution is irrelevant.

The same isn't true for the pump. The life is less because a half worn pump won't winch and drive properly at low rpm. At full pressure the pump-leak-back is the same at any speed. At some point you overcome that loss via shaft speed and start winching. That's fair though, and it's why hydrostatic machines use axial piston rather than gear pumps like us lot

I run 80 litre a min at 3000 rpm.

I cut out the front crossmember with 3mm 50 X 100mm box below the rails. It mounts the skid plate stuff.

My pump is mechanically fixed to the engine, not the chassis. On a Serp engine you could be pretty short, even with the dog clutch? It depends on your flex coupling and crank adapter.

At 3000psi and 3000rpm it is over 30 HP?

If you are in the dry I would go belt and if it runs in deep mud I would go direct front PTO.

No argument from me on the work load. Front PTO is a real challenge to build

But it is oh so good to use

Perfect set up?

Twin pump on front PTO to make two separate systems. One drives the winch, the other drives a motor in the transfer-box PTO hole for perfect winch-drive with good engine speed.

(My winch and drive engine speed is below 1500rpm engine)

-

Driving trucks back in the day I would probably go with a 90, move the axel back one step and put a dummy steering axel where the old rear was. It's a well proven chassis formation. (3 axel twin steer)

-

Other than popping cv's I have none. Don't boot it on full lock

especially backward!

especially backward! -

I still think it's a better concept as a winch. We really drop pull strength when the drum is full on ours!

-

The best thing for 'home fix' is probably single-pack epoxy glue. You can shift the corroded ally with the same phosphoric acid that eats rust. Rough the surface of the new sheet, apply the glue, stick together and heat it until it goes hard.

The glue is typically grey, stored cold and used on car and plane manufacture. We use loads at work. It's also great for 'caulking' joints.

-

I think it will do very well outside the EU. It always did.

It is a very good 3rd world country vehicle. I'd rather see it move to somewhere that folk need it than just finish.

I can't quite see why having two massive chassis rails is bad for a 4x4 and fine for a Mitsubishi Canter though? Hardly the first time a viable design got mullered by legislation. Why would LR or Tata spend money on the design when they know it's got a gov legislation axe hanging over it. It's boring cycle of "we need UK industry" followed by a letterbox full of reasons not to keep trading.

-

plastic sink drain pipe with blank caps would be good for storing rods with a dry-gel bag lobbed in. The next enemy after damp is chattering, so make sure they are rammed in with something else or the flux knocks off

-

I'll be straight up honest here and say you can shim the crossmember under the gearbox to change the position of the outriggers. Those crossmembers vary on production tolernce, as does the chassis rail width.

I'd buy cheap and mod it.

The best you can buy is a knock down kit. I managed to get an S1 dumb iron in bits and it was easy peasy to make it fit. It's a shame its not how they all are.

Lazer has got so cheap I'm into drawing bits on CAD and getting them made. I can then choose where it joins and how. It's the only option for the transit chassis as it is 24 year old.

-

Way ahead of you! Already got multicolour flashing LED's in the ear

But I am thinking the eyes need something? I just bought the Maplins flashing led kit. (As you do).

-

-

I guess the main argument for a computer one is rate of change. For low use you might have a 'dead band' on the controller of 10-15psi. If it has a sudden drop due to high air use it would be better to cut the compressor relay in sooner. If you monitor the pressure accurately you can write a PID routine into the computer based on pressure-drop vs time.

-

For the switch idea you have a pressure switch set at full pressure and another 10psi below that, (both green led), and yellow set below that and a red set at 60psi. I can't see the pressure bands on the eBay ones, but they are less that six quid each.

-

With a masters in Mechatronics I hate to say that a few pressure switches at different settings might be better.

I'd put a 52mm gauge in the roof so you see it in the rear view mirror though.

Or go the full Rasberry and make it do other stuff

-

Yeh, but if you 'dust' an etch it won't etch because there won't be enough active acid to cut through the oxide ( I was told by the supplier of the two pack aircraft grade etch primer) .

-

It all points up on the RRC. The manifold is compensated to keep the carbs level. To miss the sump it's likely they kept the same concept on every 'coiler' after that.

-

We may be five hours of tacking and welding now? Probably a fifteen to twenty hour project? It's always hard to tell.

So probably nearer thirty by finish

-

I think it will need 'head lights'

-

Yeh, I think so? Society has a very low threshold on 'what it can deal with'. I should build a mecha pony to go with it maybe?

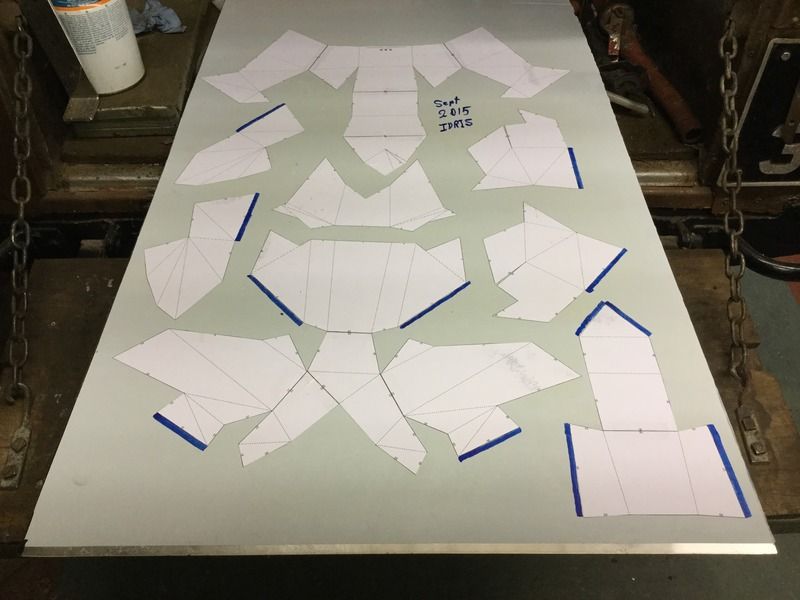

The trick was to lay all the patterns out flat and start joining some parts while seperating others. Then I had a true left/right template to stick to the ally. (Before it had all fitted on A4 sheets). After using the spray impact adhesive I went in with the marker pen and added likely tabs. In this case plastic-protected sheet was perfect. Once it was all bent all that bending template info just peeled off !

There are 18 sheets of A4 in the PDF file.

It should have a horn. The horn is good, but a bit spikey in ally. I've gone for cutting up a blue hand brush to make a Roman style helmet plume.

Sat there it weighs 683 grams.

I wonder if the head band will be a total butt to fit? I can see double sided sticky strip coming into play.....

-

I was rather taken with Wintercroft masks while I was on Etsy. (Etsy is worse than EBay for dropping cash). For five pounds and something you get a PDF file which is the equivalent of your average dress-pattern. You print it off, check the scale by measuring the datum line is 150mm long and then start with the scissors. That done you stick the patterns to cardboard and start with the scissors again. Then it's sticky tape time to form your very own 3D mask. Cool

There's bears and foxes and all sorts!

But you know what's nicer than cardboard? Yep, aluminium

And you know what's better than sticky tape? Tig weld

Unfortunately I'm not a red-hot Tig weldy person so Tony from work has been popping round to join it up. But it is nice to see my welder set do some proper runs on 1mm 1050 ally.

Happy New Year

in International Forum

Posted

Happy new year