-

Posts

209 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Events

Gallery

Blogs

Posts posted by Tobias

-

-

Ok i see.

- find the connectors (if not found splice them in(if no wires-problem))

-install downpipes with cats and sensors

- find and change resistor

All?

Tobias

-

Im fairly cerain that there are no connectors in the loom, since the carnever has had any oxygen sensors. That is not my biggest concern. Im more worried that thete is no cable in the corrrsponding place in the engine ecu connector. That would make splicing in the connectors so much more difficult.

More input?

-

Hello

I have on my doorstep a 1996 Disco1, 3.9 V8.

it was originally built for Egypt or Saudi arabia, not entirely sure, it anyway doesn't have any catalysts or oxygen sensors (lambda sensors.) Hence it fails the emissions test done at the MOT-equivalent here.

We happen to have dismantled a 1993-ish Rangie with a 3.9, Swedish spec, so has/had the cats and lamda sensors.

As far as I've read up in the RAVE, I only need to install the cat downpipes, wire in the lambda sensors in the ECU loom somewhere, change an "engine trim resistor" to a different value to tell the ECU it now has lambdas and cats and I'm good to go?

Any ideas on this?

The car is not mine so I need to be fairly sure about the scope of the work before we start.

Thank you for any input

Tobias

-

-

I have a telestart I'm willing to part with.

Can look up exactly what it is (number etc.) tonight.

Never been used.

Give me an offer...

Tobias, Sweden

-

A friend of mine has one similar to this:

http://www.volvo4x4.se/89059.asp

It's called TGB20 and has a slightly longer load bed and wheel base than TGB13, otherwise similar.

It's in used condition, some lamps may me broken/missing.

Portal CV joint rubber gaiters are recent upgraded PU-rubber stuff.

Brakes OK.

He is interrested in upgrading to TGB40, 6x6 scania truck, so it's for sale.

PM if it sounds interresting.

It's close to Stockholm, Sweden.

Tobias

-

<OT>

Slightly off topic but a 1056 or 956 as we used to have should start fine down below minus 10 there is a heater plug in the inlet and this also adds fuel check this is working and they are also well known to need a fast spin an uprated starter motor is available from end of production models this has helped some people and because the battery cables are so long these need to be in tip top condition as does battery

but the thing these engines need is cranking speed oh and they sound bloody lovely

Andy

Thank you!

Will check cold start device and make new cables from battery to starter.

T

</OT>

-

Here in Sweden it's more rule than exception to have in-block coolant heaters. In the more northern parts you even have power poles at many work parking lots to help plugging it in.

They are installed inside a core plug in the block, to get it into the coolant.

There is no forced movement of the coolant, so the power is limited to about 550W.

If used for about 1 hour it will heat a normal engine. In our tractor, an old IH 1056XL with a 6l iron engine it takes about 3-4 hours at -10C to help in starting.

Normally a petrol engine with a healthy battery is no problem even in very cold weather, but diesels can be more tricky.

I have just installed on in the wifeys P38. Knockin the core plug in one end, pick it out, insert heater, tighten, refill coolant, install electrickery bits and off you go.

I'd say 1-2h installation. here we also run a tee inside to run a small electric heating fan to have the windows frost free in the morning. that adds 1-2h to the installation, depending on how much carpet and stuff you have to penetrate to gain access.

This was a DEFA unit, can be found at:

http://www.defa.com/finn_dok_h.php3?merke=LAND+ROVER&modell=RANGE+ROVER&type=2〈=3&ndid=

The 346 should fit, as long as there is room around the core plugs on the left side. I used the rearmost one of the three.

Tobias

-

Thank you Zim, will order one tonight.

How many rings to do a seat?

Tobias

-

>Get some hog ring pliers and rings...

What's this, please?

Tobias

-

We are now thinking about making our own conversion for two sets of axles. Any reason not to run RRC/Disco disks and calipers?

In Sweden the equivalent ov DVLA rules are such that as long as we retain the brakes and suspension setup an axle swap is not a large modification.

Tobias

-

You can see some different stud patterns here

http://www.scason.fi/english/index_nastat.php

We mostly use the ones most similar to S and MAL.

Tobias

-

Here in sweden studs is more the rule than the exception in winter.

For the TD5 Disco2 we studded BFG TracEdges and now for the missus P38 we have studded AT2s.

Studs are available here and i can send if anyone would like to try.

they are available in defferent diameters, lengths and weights.

For inserting into the hole a special machine is used. Like a pneumatic plunger with three spreading prongs that spread the hole so that the stud can fit.

We use 8mm diameter and around 10-14mm length.

I Drill with a 4,5mm drill bit with a piece of air holse as stop to get all holes the same depth.

if tires with predrilled holes are used the tire shops refuse to stud in these holes and drill new ones instead. i myself has had success so far with running the dril bit up and down the holes a few times to clean out debris before mounting the stud.

I can take som pictures later if wanted.

Tobias

-

Or, use the stronger LT230 and a 2 wheel drive conversion kit from the same company above

Not that I can find it on the site, mind you... but it does exist, doesn't it ashtrans?

The problem is, it seems that the exact functionality of the original transfer gearbox is essential in this group. The Ashtrans fart time conversion would allow 2wd-low, which is not available on the series transfer box.

A cheap 90 is of course a better option, but they are stupidly expensive here and we already have the 90...

T

-

We are tossing ideas about what would be the easiest/best path from here into a cheap and reasonably competent trialler built for the Eurotrial Standard reglement.

We have a series 3 88 where a mercedes 200D engine is coupled to the original gearbox

We have a Volvo 745 with B230E and ZF autobox in good shape

We have assorted bits and bobs.

Install RR power steering and run it with the Merc200D? The engine is dead for some reason we do not rremember, but surely we can get it working.

install Volvo with ZF, but how to mate it to the series transfer case? It seems that it is not allowed to mate it to a LT230, the original transfer box needs to be installed for this set of rules...

So can this be done and any ideas on how?

Tobias

-

Works wonderfully!

Thank yiu

Tobias

-

Anyways I hear there's a problem finding some steering rod end for those volvo portals,

OT!

Not anymore!

A guy in Sweden has them made now.

http://www.fmv4x4.com/?page_id=30

No connection, other than happy customer.

/OT

Tobias

-

Aragorn: i hear you on the later oil pump, but I can not see how I can with reasonalble effort/expense duplicate the ancillary system I have now on the vee belt system.

I have/need:

Crrank, water pump, York A/C pump for OBA, generator, Saginaw PS pump for hydraulic steering.

Still I have one pulley unused for a second hydraulic pump for the winch as soon as I get too it.

They are mounted in 3-4 different planes, relative the fron of the engine, which means I have to find new pulleys, relocate all, but the crank relative the planes and find a routing for the serp belt and positioning of a tensioner and a few rounding pulleys. I just do not see how I can manage that engineering feat.

Please help me along in deciding and if the serp front end is really worth all the extra effort I really need help in managing the positioning of all the pulleys!

Tobias

-

Aragorn: I'm not sure it measures lower. It's just that when I feel over the border between top deck and liner I can feel the edge between deck and liner on most liners, but not No2 on right. But today I felt it, so it is a bit different around the circumference of the liners, so not a good measurement at all, in fact!

Will look for pressure testing facilities here.

If I have to go serpentine I think I'll ditch the later timing cover and go for the earlier.

What is it that is so golden about the later oil pump? Is it mainly the drive by distributor or is it something else as well?

Tobias

-

Thanks, Aragorn. I tried to check the block faces and could only measure less tha 0,05 mm. So if there are normally no tendencies for local sinking, as in 4-valve head designs, I should be fine.

Any ideas on how to check liners? The heads are marked 45 00 so I assume week 45 of 2000 which means the engine is a very late one. Soe people seem to think the liner issue is not as bad on the latest ones... I hope it's just head skimming and gaskets

About the front end. I really want the pulleys to be vee-pulleys, since Ive all vee belt ancillaries and built up brackets for all the ancillaries I want. I'd really not fancy nouting new ancillaries/pulleys to get it all working on seprentine. Esp. the york AC pump for OBA.

Does the water pump for serpentine front end rotate in the same direction as for a vee belt system. I.e. can I run the serpentine water pump in the same rotation as the engine and just make up a vee belt pulley for it.

Should I drop my anxiety and run a serpentine front end?

T

-

Iiv'e started tearing down and looking at pieces more:

The water pump has some scratches, is this worrisome?

There is talk about a spacer for the crank pulleys when using a 4.6 front end.

When I measure crank nose to oil pump gear I have 48mm free length:

while the crank pulley itself is only 42mm front outer edge to the ledge where it will hit the seal.

Is this why I need the spacer, is the spare to sit on the crank nose before the pulley?

When I measure straightness of the heads they are curved 0,25 resp 0,30mm lengthwise and both about 0,10mm crosswise in the worst spot. This seems excessive and should I have them faced?

I will put it on the engine stand and have a look in the sump and lift a main bearing or two, but if that looks as fine as the upper end, I'm tempted to just slap it together, with perhaps a refacing of the heads and new gaskets and leave it at that.

Tobias

-

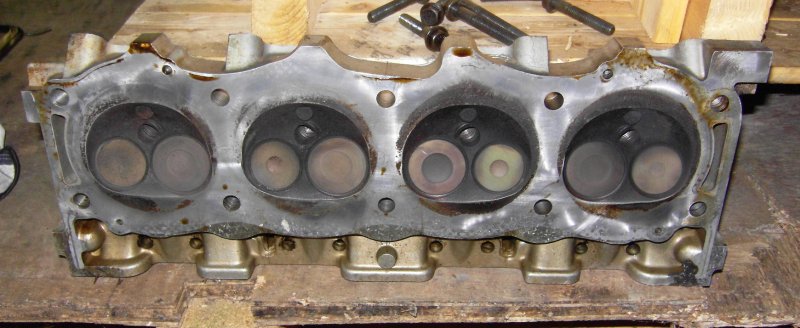

Now the engine is in the workshop.

Just had to pop the lids and verify that it's really a 4.6, and

YES! it is!

Engine number: 60D14595A

No sign of washing in either piston crown or head combustion surface.

When i feel on the top deck of the block at liner block interface i feel the liner sitting proud of the block, just creating a tiny ridge possible to feel by the fingernail. The number two bore on the right however has no such ridge. Is it a slipped liner?

There were no headgaskets in place so no autopsy were possible on those.

The history of the engine is completely unknown. It has it's origins within the warranty loop, so in some stage it has been exchanged for a good engine by the factory. What would cause that? What should I look for, apart from "slipped liner"?

Tobias

-

Thank you, Cowboy. So no real hurdles, just better and less godd mixes.

I will get back as soon as I've taken a look at the mess.

I have a flapper intake complete with injectors, regulator, TPS and so on which I had intended to put on the carbie for the MS conversion, but if the 4.6 intake is better I will of course use that. We'll see.

T

-

I Have a 3,5 carbed engine, normal dizzy and vee belt front end.

I hay be able to get a cheap 4.6, unknown condition and at the moment unknown what parts might be there and missing.

My intention is to build a new engine with MS'n EDIS with the best combo in the cheapest possible way.

I have a TF727 that I intend to keep using.

Will the flexplate/adapter fit the 4.6 crank?

Starters fit across?

Can I build up a vee belt front end on the 4.6 block?

Will the 4.6 heads fit my 3.5 block

manifolds?

Other pit falls?

Tobias

Convert 1996 Disco V8 to cats+oxygen sensors

in International Forum

Posted

Which leads me to believe that without resistor it would pass emissions?

NAS would be stricter than or equal to Euro spec, I guess?

T