-

Posts

864 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Events

Gallery

Blogs

Posts posted by Adam001

-

-

I'm just about to do this along with a load of other panels,

I've ordered high temperature (150C) Spray adhesive ... http://www.ebay.co.uk/itm/320768691072?ssPageName=STRK:MEWNX:IT&_trksid=p3984.m1497.l2649

and vinyl leatherette

Wanted to use bull hide, but can't stretch to it at the moment. Simply plan to stretch the vinyl over the panel and if it won't match the curves I'll add in a stitch line.

-

We used to do 15+k a year in our 2.5td 19J 110...think you'll be fine!!

I now do 12'000 a year with the 200tdi conversion.

-

Haha!! I should point out that picture is purely just testing lengths

I am very methodical, it will be a work of art

-

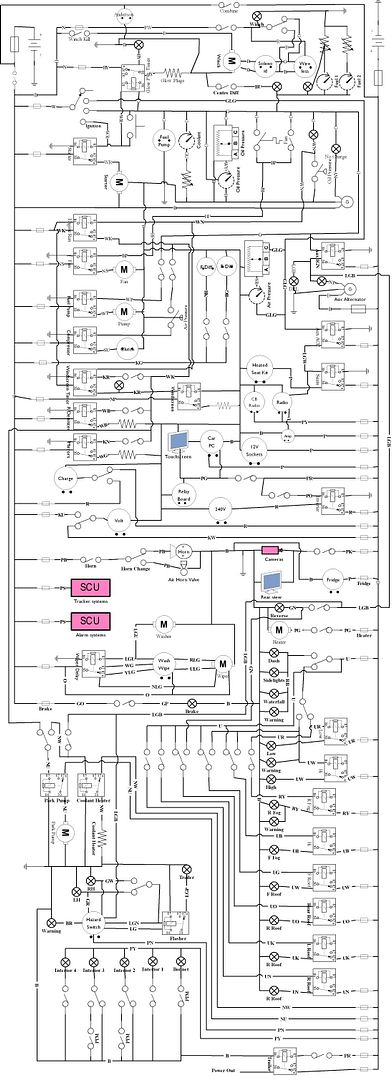

The symbols for the front and rear diff are for the ARB Locker Solenoid Valves (not that I have them yet, just future proofing)

The clutch is the Electromagnetic Compressor Clutch for the on-board air system

Just ordered the data cables for the carpc too...

It's coming together now....if the diagram looks complicated....try this...

lol

-

If you want to be completely thorougher just put a switch inline with the relays coil circuit for when you use the winch. You won't have any issues then. The X-eng will be perfect for the other things you mention.

-

Can some one please clarify some points for me if I fit the X-Charge unit.

1. Can I fit batteries with different amp hours.

2. Does the X-Charge relay work but cutting the voltage from the main battery and only uses the aux battery for say a winch.

3. Is the relay voltage sensitive.

I have two good batteries and just wondered if it is possible to use them because they have different ah.

I have just ordered an X-Charge system from Si.

The X-charge requires a feed from the alternator no charge light wire (field exciter) to the coil of the split charge relay. So when you start the car the relay links the 2 batteries and automatically disconnects the batteries when turned off. It is not voltage sensitive, if you give it 12V on it's coil it will connect them the same as any other relay.

You can have 2 different batteries using the system with differing amp hours, so long as you install it as per the instructions and do not leave them connected without the engine running.

The kit is ideal for running auxiliary equipment but a word of caution, I am not trying to go against x-eng here (I have their X-cap and X-brake) but this split charge is NOT suitable for winching or high loads. The 100amp relays are strong enough and if the kit still uses 16mm^2 wire, it is not heavy enough. Still better than a small relay, but if you want to do high loads, get another product that uses a device with a greater contactor area and a minimum of 25mm^2 wire (35-50 is ideal, 50 essential for prolonged winch use). Average 16mm^2 wire has a safe current handling of 100amp...a basic winch pulls ~400.

-

Yeah mine was different, the bottom didn't seem right, had no form of seal, did it a while ago so can't remember exactly why it didn't work...maybe I got sent the wrong part or something.

Current set-up works so I'll just keep with it for now...till something breaks then I'll give it another whirl.

-

Yeah I did buy a 300tdi dipstick and tube, tried all sorts of combinations but it failed miserably...think it was a issue with the adapter at the bottom.

-

Just messed about with it, applied some generous heat to the tube off the car so it didn't crack then just bent it to suit.

-

Conversely...I've been through 2 sets, mostly doing m8s though. Current one is welded and works perfect now

-

Those rivnut pliers are ok for use with aluminium only up to m8, no larger....but to use them at all you have to do some welding on the tool, even with just occasional use.

Simply, they are just not strong enough and the tops bend outwards as you apply force. If you look at the top of the tool you will see the center shaft and the 2 round bits that act against the center, they are only held against the shaft by the sides of the tool and they will slip after a few uses.

You can get around the issue by just welding a piece of metal over the top of the tool to hold the 2 sides together.....or put a G clamp round it to hold it together!

-

is this to light up another light? or automatically turn the engine off? or another reason entirely?

if the oil pressure light does lose its earth does it light up?

Just trying to understand why??? lol

Jad

The purpose of it is to make a wire go live for use with ancillaries and gear...but only when the engine is running, not at any other time.

It's mainly me just being a bit fancy and making the system fool proof (me proof).

I plan to use the live wire to provide the live to the switches for the heated windscreen, mirrors and rear de-mister, but also to provide a safety feature for the electric coolant pump and park heater.

adam fair play to you for doing this im having trouble just reconnecting my old wiring loom

I find it easier to build looms from scratch than fumbling around with (poorly designed) standard looms!...or maybe I just enjoy complicating things?

-

Well yeah, or the oil switch has fallen off

I should have said..."When the oil pressure switch opens"

-

It's a bit crude, so some things may only make sense to me! I went on a bit of a safety rampage with fuses and relays, I don't like anything unfused!

I've already noticed one mistake. The engine run signal wire now uses 2 relays, a standard 4 pin and a 5 pin changeover relay so when the oil switch loses it's earth you gain a positive signal.

So...we now have 27 relays

-

Don't know what your saying, there's only 26

-

I think I follow you.

Your 2.25 only has a feed and no return from being a carb vehicle correct?

For the 200tdi you have 2 options if you have 2 tanks.

One is using 2, 3 way valves to send the feeds and returns back to the tanks.

Second is to loop the return back into the feed on the engine side of the valve using just one 3 way valve. But this can have issues with air locks.

-

Well took me longer than I thought....but here's my first draft...

As a brief summary, the system uses 2 batteries and 2 alternators using the ignition switch to control both systems.

I've ordered all my wire and I expect as I install it I'll find more improvements! Once I'm all done I'll do a neat version!

-

There's not a "corresponding hole", the hole in the bulkhead leads directly into the lower part of the dash. Which means that this has to be warmed up before there will be any heat inside...

Yes there is a corresponding hole in the dash section. I just re-assembled everything on mine, looked at the 2 holes and saw little point enlarging the hole. But then my bulkhead is galv so didn't want to!

-

Good shot of my set-up

200tdi Discovery Engine

300tdi Turbo and Manifold

2.5TD Airbox - Plumbed around the back to the turbo

300Tdi Safari Snorkle

-

Seems standard is the best option for me then! Great advise all!

Going OEM HD standard so I'm better protected when overlanding, should give a nice ride+height and for simplisity!

-

Cheers guys

Mike, the height of the rear on yours looks about right, ideally 1" higher than that, and matching on the front would be ideal.

I am planning on using it for overlanding, but it will also be my daily so needs to handle laden and empty! I don't ask for much eh?

Bit more hunting...and re-reading peoples thoughts...think I'm going to go for the same set-up that Chris above has and keep the helper spring set-up in reserve. If I buy the springs from paddock will I end up with Britpart??

Helper Springs being RRC3266, and RRC3355 and RRC3352 for the retainers. Is this the better way to get the heavily laden assist, or are air helper springs better?

Ah just read the RKB101111 are progressive, so shouldn't really need them

-

my 110 rides on OME springs 751 up front & 755 on the back, husky winch & bumper up front.

Quickly looked them up on Devon...look great but pretty pricey! On-top of the rest of the build I'm looking in the region of £200 max ideally

-

The "technical datas" Terrafirma and others are stating by saying "+50mm" are just rubbish IMHO. OME for example give the correct datas by stating spring capacity and unloaded length.

+50 mm compared to what? I bought a pair of light duty rear springs for my '97 110 CSW. I found what seemed like "real" data on them and they were the same as the OME springs on my old One Ten, 270 lbs/inch.The result was that they made the rearend lower than the genuine Td5 springs I had on...

I know what you mean, I have reasonably reliable data for what the standard ride height for mine should be...but I'm trying to stay away from working it out from spring rates...as it's easy to go wrong if you get one wrong bit of info...would rather know what people have fitted and do the exact same

-

Cheers, Appreciate it.

Had mine lifted for so long I can't picture it!!

Re-covering defender lower dash panel

in Defender Forum (1983 - 2016)

Posted

Yeah, using a heat gun for the corners helps, the foam they are referring to is 'scrim foam', typically 3mm. I'm not using any for mine, if it fails I'll let you know.