-

Posts

2,571 -

Joined

-

Last visited

-

Days Won

15

Content Type

Profiles

Forums

Events

Gallery

Blogs

Posts posted by Nigelw

-

-

Ok, so tech time....

What is the maximum degree bend I can put on a drive belt within a given distance?

And what is the minimum run on the pulley for an alternator roughly?

Will a serpentine belt give the best flexibility for a one off custom built install?

-

i'm getting to the stage where i'm getting a strong sense of my own mortality,and Vapor builds on the internet are much easier and come together much quicker than actually doing it in the metal. But if there was some local enthusiast who was genuine about building a 6x6, I would seriously consider donating my old thru drive drop box,prepared107'' chassis, rear bogie spring pivots etc to the cause when I ready for the old codgers home.

It's funny how you used that phrase as I liken some of the thing's I read on some forums as exactly that!

I have a very current project Discovery1 that is eating it's way through what cash I have faster than an alcoholic in a bar, but slowly it comes together, to be honest I have always been a creative thinker and although on this poxy rock there are really very few mods you can drive the roads with but back in the UK before the economic crash I was busy building a 6X4 RRC fifth wheel tractor unit to tow a home built custom fifth wheeled horse box for my daughter, but the slump and a money hungry now ex wife saw the end of that and a couple of other old trucks I had. But for the future building something for the farm or just for use on our 8 hectares would be enough, and an engineering project for something different in my own personal take on it, I am trying to organize two projects for next winter, one personal and one a joint venture with another guy, with a 130 Defender, I am belt and braces here as I have been let down on projects so many times before that I know if I don't set money aside and get a plan together I will end up sitting on my hands next winter due to being blown out at the last minute and that really won't do!!

Lot's of creative thinking came through from this thread but for me now it has been done to death and with so many concepts already in it I doubt there could be anything new to come from it? I would like to see a separate thread from tuenico showing us his way forward so we can keep this as just reference for the ideas, through drive axles that would be custom made and purposely heavy duty compared with Rover axles would be a good way forth but expensive!!!

-

Can I tempt you with this little trinket Mr. Van Snorkel?

Found whilst surfing the tube, sorry it is a little grainy but very impressive!!!

-

I've seen diffs from the factory with RTV sealant used instead, on a Td5 90.

This was on a 1994 200Tdi Disco 1, prefer gaskets, sealants worry me when applied by the wrong hands!!!

-

Good luck with the demonstration!

I recently watched a short video by ellbarto(i think?) about the lanes and proposed closures of yet more lanes.

I bid you success and unfortunately being on the bigger rock and having heavy work commitments means I cannot attend, but do set up a donations page, it is a worth while cause, but will GLASS not help with donations or is this against their wishes?

-

I know this may not be PC but see here...http://www.lro.com/forum3/viewtopic.php?f=2&t=86891 I tackled a blower switch on a 200Tdi D1, looking in my spare room for my old 300Tdi blower box but can't find it to give a comparison I'm affraid.

-

Now have two thick ones embossed with makers brand, in honesty I prefer not to use sealant for that reason but also possible contamination if it goes beyond the jointing surface!!

I welded on a new diff pan for a mate last weekend and I noted that there were no gaskets on the diff or the half shaft flanges just sealant!! I reassembled with gaskets as it should have been done,guessing someone else had been there first?

-

A thin paper gasket is normal, thickness wise I'd say around 0.15" - 0.25" . Normal practice would be to coat it with a thin smear of non-setting gasket cement before installing.

Super, thanks Boydie, but not sure why main dealer would supply two completely indifferent thicknesses, will find out in an hour when I get there.

-

The first link here is for the resistor pack from Britcar and the second link is for an ebay item but look at the picture more for the location of on the heater box,

http://www.brit-car.co.uk/product.php?xProd=92897

What year is your Disco?

-

What is the typical thickness of a stub axle gasket?

I ask as I was forced to buy two from the main dealers and when I got home and took them out of the nice shiny plastic packets they are both different thicknesses!!!

one being no thicker than 2 sheets of printer paper and the other is more like that of a cheap Christmas card!!! Yes both from main dealer and will be going back to speak about the issue but what would be the norm? I assume the thicker of the two?

Any ideas?

-

MTF 94 is the standard now, but I will stick with Dexron2 in my LT77.

I would never put moly in a gearbox. Moly is a fantastic lubricant for sliding surfaces such as gear teeth but is entirely unsuitable for use on ball or roller bearings as the reduction in friction can cause the bearing not to rotate, eventually causing a hotspot and weakening/wear on the bearing itself.

Moly in the engine is great though - its all sliding surfaces there and most modern engine oils contain moly in some quantity or other. -

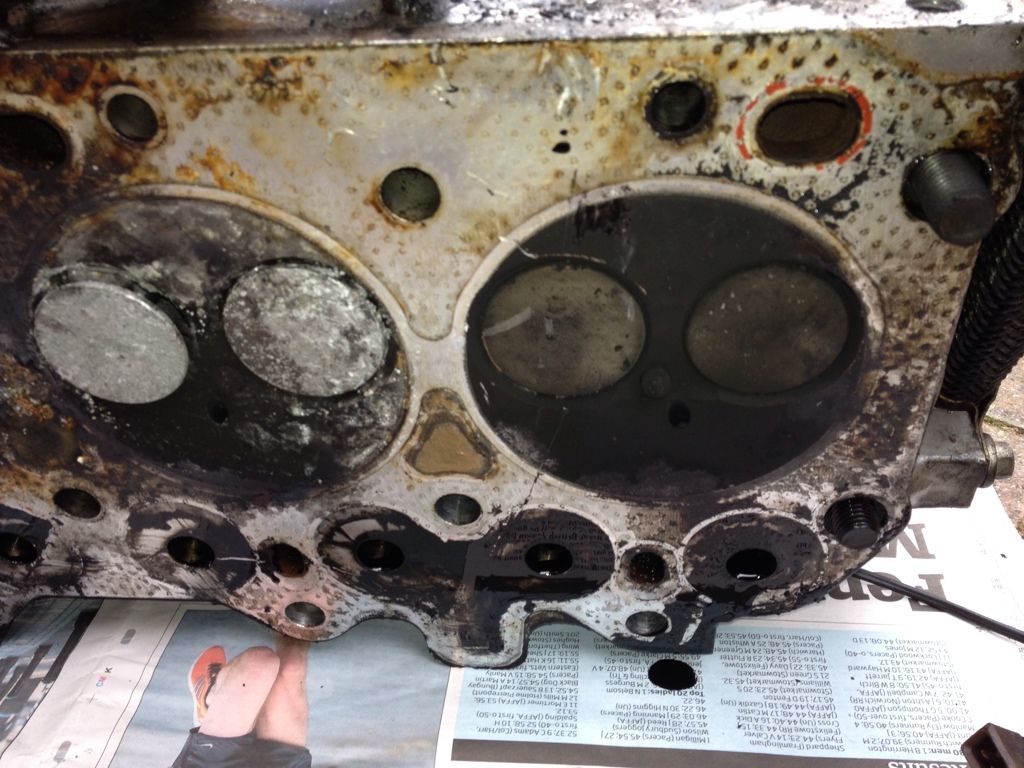

I haven't any pics of the engine i've used, but here's about the worst one i've had.

that's nothing, dodgy head is all now take a look at this!!!

Proper killed that one!!! I am still waiting for the lad who owns it to send it to me as I want to make a coffee table from it! Very industrial don't you think?

-

For a double diff setup I will need:

Tools

Grinder (have it 0 Eur.)

Drill (have it 0 Eur.)

Welder (have it 0 Eur.)

Tapping set (have it 0 Eur.)

Parts

Rover diff (have it 0 Eur.)

Studs for fixing rover diff to new tapped holes (have them 0 Eur.)

Spare propshaft for adaptation to new length (have it 0 Eur.)

Two Rover diff gaskets (Paddock 0.61 Eur. + VAT + p&p

Paint

In theory with some paint and less than 2 Eur. I could build it

I so wanna see how you get on with this!!!

I have an idea that would use a double drive from the back of the transfer case an altered diff nose angle and a 45 degree bevel box mounted on top of the mid axle, but my build will be on a self built space frame to get round as many of the obstacles as possible but be beefed up as the hardware is made to run properly I think, not road going but a type of farm vehicle built for my own pleasure.

-

Scrap it, make your life easy, I had a lot of stuff even axles etc advertised for more than 6 months and had a lot of calls and folk come looking but not a single taker could hardly give it away!!! Scrapped in the finish and even the 10 spline axles just got scrapped and they were complete and had been advertised for more than 3months.

If you like having your time wasted then ebay, I would just scrap it, a problem in the making trust me!!!

-

i think you'll find at the moment lhd ones going for quite a bit more than rhd. UK used car prices are pretty cheap and combined with the current weak pound, lots of vehicles are heading off shore, so you've got a bit of competition in your hunt for lhd vehicles.

english is pretty widely spoken in north western europe, so you could try germany, benelux countries and scandinavia, but i think you'll pay much more buying from one of these countries.

another option might be the middle east.

Do not waste your time in main land europe!!! I live here, if I said it was stupid prices then that would be an understatement!!! They sell whole cars expensive and broken for parts they make almost twofold the price!!!

You might get lucky but even rotten D1s with no MOT are 2000 euro!!!!

-

I got a couple of questions about that engine!!! Have you got any pictures of it with the melted piston and how did you come by it?

-

The double-faced diff trough-drive system, with a propshaft runing car diff to trailer diff will be extremly easy to create. Unfortunately the CW of car diff will be overloaded, propshaft will be too short for adecuate articulation and also will be extremly exposed. But ease of manufacture is there, and maybe for a simple test drive...

.

What is the distance between the two diff? Axle casing width? and what of the pinion? Would it be possible to shorten it at all to give greater prop length?

-

With the pulley belt on diff arrangement,would you not have a problem with the propshaft to the trailer clashing with the LandRovers rear crossmember? or would you run a 2 piece propshaft with a centre bearing under the crossmember?

That would make sense but would it not become compromised then? above the hitch is protected, below is open to a wallop!!!

I came to the conclusion that some sort of hydro drive would be best suited to a powered trailer, and could be coupled to an electronic control valve with a transducer that would send a signal to the valve to open or close more depending on speed of the output shafts, a dash switch and free wheeling hubs would see it redundant when not needed ie, in high range, but low range would be quite suitable for it I think?

-

You really are my hero Jeff

Another D1 saved from the scrap yard!!!

Any chance you might happen upon making a panel press and knocking them out in competition with YRM?

-

Right appointment booked for Wednesday and just gotta get my camera sorted out now as bathed it in EP90 over the weekend but worst case a cheapie just for the photo's.

It's not the biting!! Just the amount of sedation we have to give them to be able to take the pictures makes them heavy and hard going, but I tell ya, you try and get a 0.6mm needle into the vein of a young horse who has only just come in from the field and has never been handled before, gets a little bit exciting!!! One of our vets had a fractured pelvis when a 2yr old stallion suddenly decided the prick of the needle was more than he was prepared to take!!

Pictures to come on Wednesday!!!

-

You MAY get lucky with getting cranked arms through if you paint them black. Maybe.

I am gonna buy me some shares in Akzonobel soon for the amount of black paint that is having to be applied to my shiny new parts!!! I have got to paint the springs black, the axles will have to be painted black too once the ARB brackets are cut and ground off, the trailing arms and I am hopefull they wont notice the two new black air tanks under the body now?

I am ordering 20 liters of waxoyl black to do the underside and all the cavities so everything will look almost new under there!

-

Gwyn Lewis' heavy duty trailing arms are worth a look...

http://www.gwynlewis4x4.co.uk/page17.html

Reassuringly chunky.

Ooooh!!! Gotta get me some of them!!!

Very worth the price for piece of mind having seen what can happen, I did consider getting some 3mm close fitting pipe and putting a sleeve on the originals, would only be a case of finding a close fit and a few euro for a couple of meters of pipe but think these are much better!

But I did happen upon an idea to use D2 front radius arms and weld the brackets on to the axle tube, meaning no matter what the suspension height is once the bolt is tightened up it is set, trouble is wouldn't get that mod through the MOT here I don't think?

-

I am having issues with thoughts that the trailing arms of a D1 are just not strong enough to cope with extra strain on them in terms of already being under tension in the chassis mounted bushings and then further tension from a suspension lift, so what is the answer?

What have other people done to strengthen the arms? And what about correcting the arm a little to relieve the extra tension in them from fitting the lift?

I have seen the X-joint http://www.british4x4outfitters.com/X-J ... 22679.aspx where there is little or no resistance to the trailing arm but again would be difficult to get it through the MOT here with that fitted!!

So if you have modded your trailing arms or have a good idea post up -

Not yet as I am having to go out on the road with my boss taking X-rays and I need to make an appointment to go and look round!!!

I have not forgotten but will deffo be next week for sure as the auction is tomorrow night and all of the X-rays are done now so a few disappointed owners who won't be taking their horses there but at least I can get on with my car now and visit the warehouse, been rubbish getting back dipping in to the forum and back out for more X-rays, as you can tell, my least favorite activity at the practice, especially when we are not getting back until 8PM and I hate young horses!! Especially those that want to kill ya

Aux drive belt questions

in International Forum

Posted

Thanks Dan,

Well what would you say would be better to tension a serp belt? manual screw adjustable idler or an idler under pretension?

think I can get at the very least 180 degrees on the pulley with least contact and more than 200 on the one with the most so slipping should not be too much of an issue I don't think, just the method of pretension to over come now I think